The diesel market continues to grow from year to year as the need for reliable light-duty. And heavy-duty vehicles increases mostly in secondary and third world countries. As infrastructure improves across the world so does the need for dependable work trucks. J.D. Power and Associates predicts that diesel sales will more than triple in the next 10 years accounting for more than 10% of all vehicle sales up from 3.6% just 10 years ago in 2005. From the year 2000 to 2005 diesel registrations increased over 80% exceeding 550,000 vehicles. From 2005 to 2015 that number further increased another 67%.

How Fuel Injectors Work

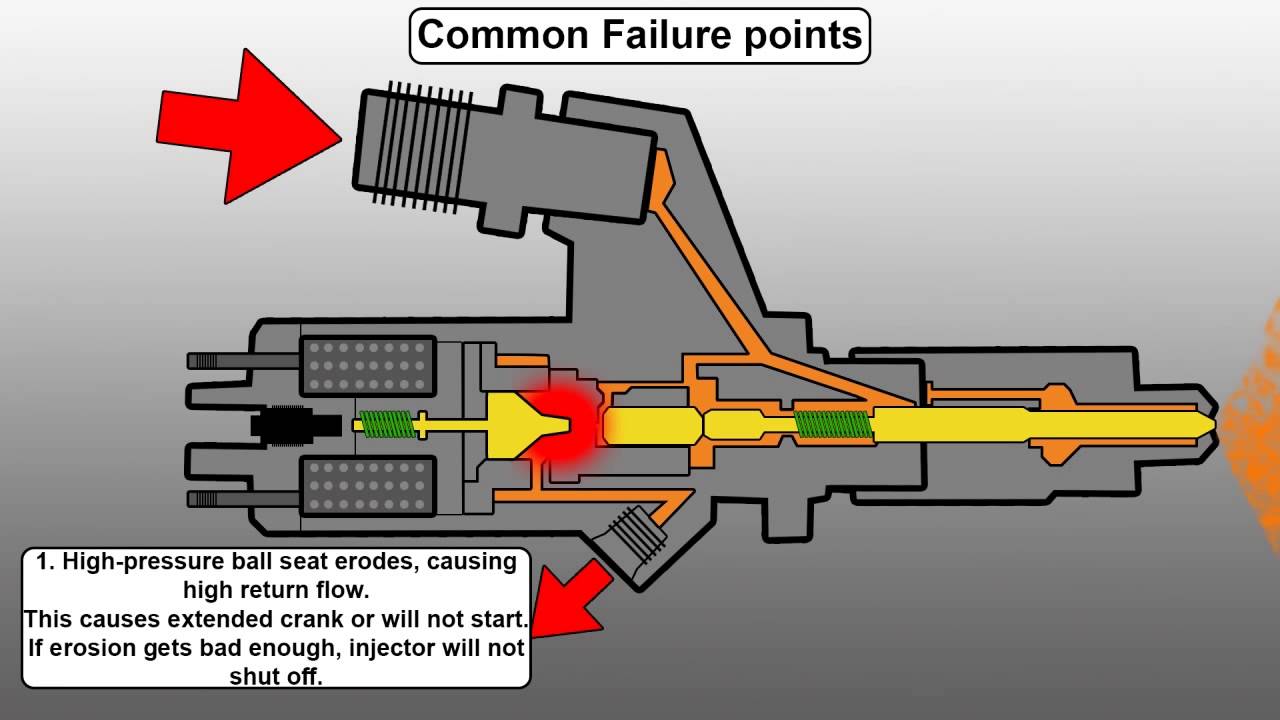

Fuel injectors are small electrical components that are used to deliver fuel via a spray directly into the intake manifold in front of the intake valve in a diesel engine. Diesel fuel injector are quite complicated. The injector has a high micron filter on the top inlet side which corresponds to small hypodermic sized holes on the bottom for the atomizing of the diesel fuel. The diesel fuel acts as a lubricating source for the injector’s internal parts. The main source of failure for injectors is water in the fuel. When water in the fuel displaces the lubricating properties the internal parts wear down quickly and the injector as a whole can fail rather quickly.

Injectors are an extremely important engine component. The injector valve opens and closes at the same rpm as the diesel engine. Typical RPM for diesel engines in North America is around 1800. This equates to roughly 140,000 times per hour! In addition to water in the fuel, injectors are subject to carbon. And dirt particles introduced into the unit via a bad air cleaner element. The type of fuel, grade and additives used also has a significant impact on the life expectancy of the fuel injector. The ECM (Engine Control Module) controls the fuel injectors in most electrical diesel engines.

The diesel injectors constantly have power when the key is turn on regardless if the engine is turn over. The ECM grounds the injector, completing the circuit and causing the injector nozzle to open. The ECM after receiving information from various control sensors determines the length of time the injectors need to grounded to inject the exact amount of fuel given the horsepower output demand from the engine.