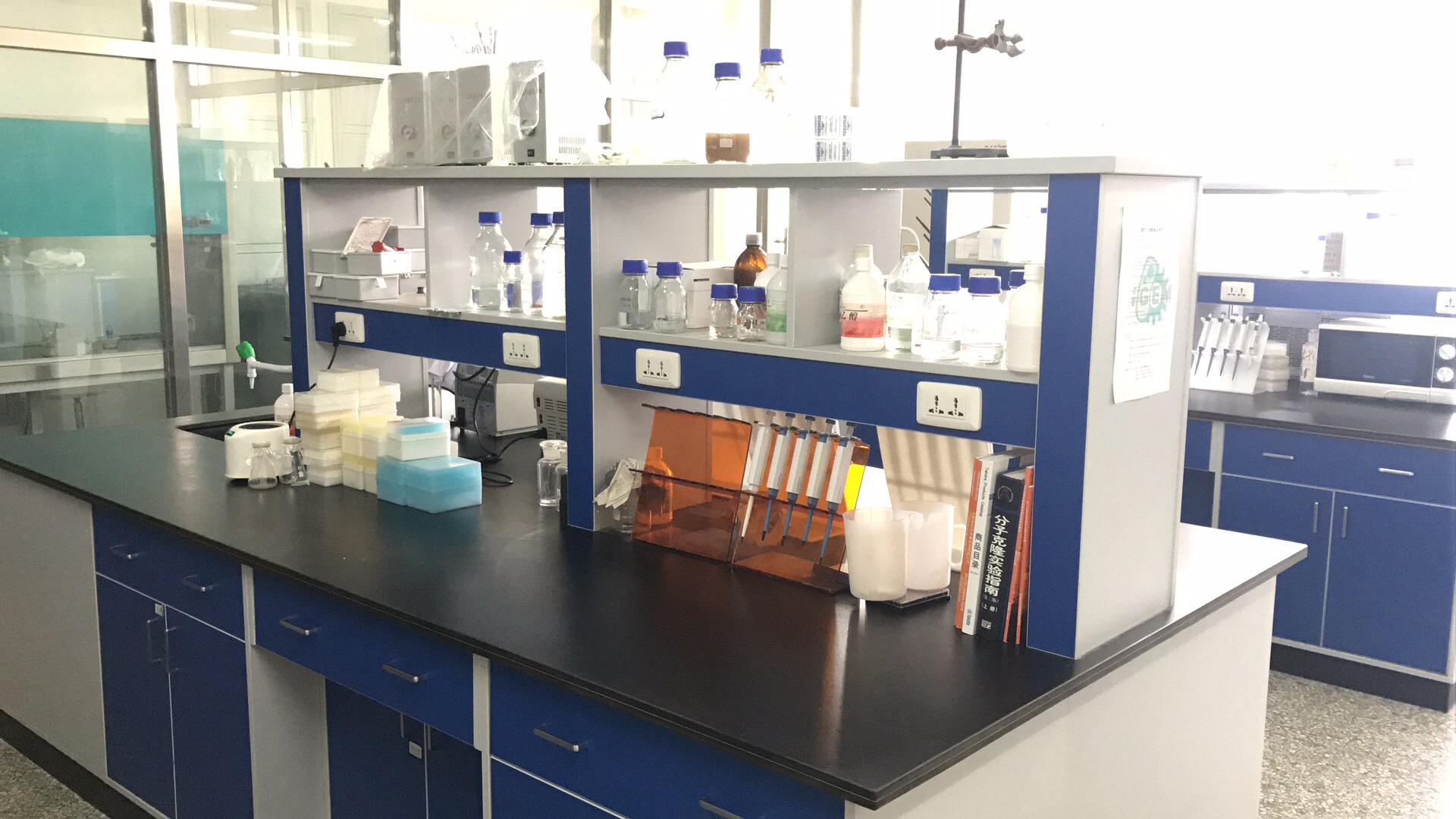

The fume hoods and the laminar flow hoods are created in a way so as to help with controlling and reducing the exposures of lab operators to any hazards or contaminants. The fume hoods will reduce the exposure to any hazardous vapors, particulate matter, fumes and the laminar flow hoods help in reducing the workspace exposure to any contaminants. The turbulent flows will follow irregular pattern of air flow along with the local air flow which will move in all the directions which are relative to bulk flow. The laminar flow will be moving in a parallel streamline which will not cross. There will not be any cross contamination in the workspaces because of laminar flow hoods. This article will explain to you more about the air flow patterns in these two devices.

Fume hoods

The fume hoods (both ductless and laminar flow hood) get used when there are materials which generate harmful vapors, airborne particles, fumes and particulate matters like silica powder, carcinogens like benzene and so on.

Mode of operation:

The air gets drawn through the hood’s opening face where the operator will work and it will get put out from an exhaust. Constant flowing of the air in an inward direction towards the opening face will prevent hazardous vapors, particles, toxic fumes from escaping through the opening hood and will keep lab operators safe. The facial flowing velocity of air will need to be high so that the hood can be effective. When the flowing velocity is low then there can be harmful vapors and particles escaping through the hood’s opening towards the users. Having adjustable windows towards the hood openings can cause a low flowing velocity. The flow hoods commonly have alarm systems in place to notify lab operators when the flow velocity becomes too low.

Use of the flow hood

The flow foods are used specifically when there is a requirement to have clean environment which is particle free and does not have any biological contaminants. Such places include areas where semiconductor wafers, tissue cultures are used. These flow hoods ensure that there is no cross contamination of air in the lab also;

The air gets filtered by the HEPA filters, then this clean air is blown all over the working area, towards the lab operators. There would be a constant out flowing of clean air which can help in maintaining uncontaminated workspaces.

The horizontal flow cabinets will be blowing the clean air right from the rear face in a horizontal direction towards the lab operators. The vertical flow hoods will be blowing the clean air right from the ceiling of the cabinets towards the workspace area where it will hit the base and then flow towards the users.

Conclusion

Both the ductless flow hoods and the laminar flow hoods are important parts of the safety requirements of a good laboratory. They help in maintaining lab hygiene and preventing any form of contamination. Hopefully, the information mentioned in this article will have helped you.